- +968-24614382

- 401, Salam Building, South Block, Salam Square, Dawat Al Adab Street. Muscat

DESERT SAND OIL & GAS CO.LLC

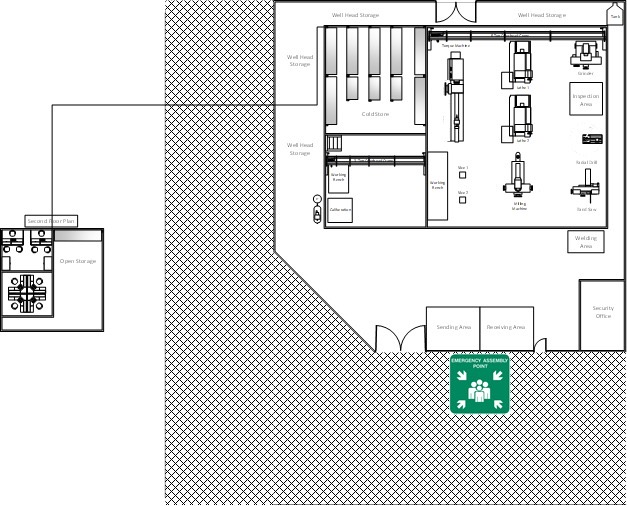

Machine Shop

Layout

Capabilities

| Sr No. | Description | Capacity | Manufacturer’s name | Qty |

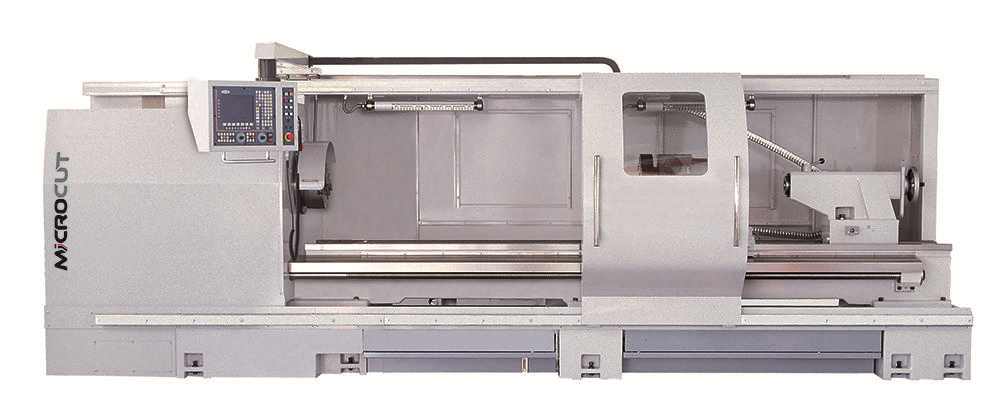

| 1 | Oil Country CNC Lathe Machine | 254mm X 1150mm | Micro cut – Taiwan | 1 |

| 2 | Turning Milling Machine | 254mm X 1150mm | ARGO – Taiwan | 1 |

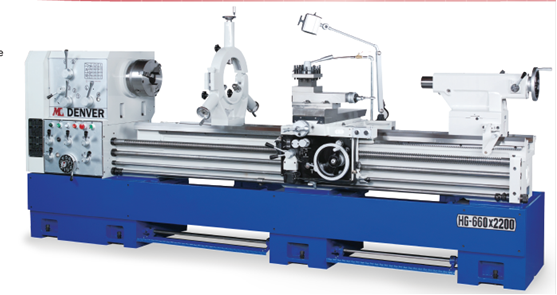

| 3 | Manual Lathe Machine | 660mm X 3200mm | Denver – Taiwan | 1 |

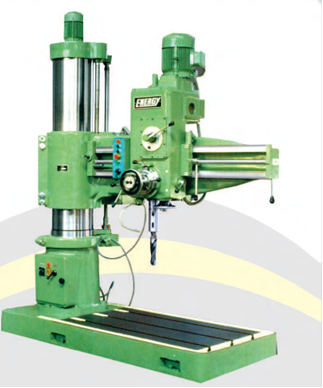

| 4 | Radial Drill Machine | 50mm X 1500mm | Energy – India | 1 |

| 5 | Tig Welding Machine | 3 Phase 300DC | GYS – Italy | 1 |

| 6 | Mig Welding Machine | 3 Phase 400A | Exagon – Italy | 1 |

| 7 | Arc Welding Machine | 3 Phase 400DC | Rexel – Italy | 1 |

| 8 | Bandsaw Machine | 530mm X 530mm | Maxmen Metal – India | 1 |

| 9 | Profile Projector | 10X magnification | Praka – India | 1 |

| 10 | Overhead Crane | 5Ton | ACE Cranes – UAE | 1 |

| 11 | Forklift | 5Ton | 1 |

Oil Country CNC Lathe Machine: Microcut Make, Taiwan

The flat-bed lathe BNC-3500 with rigid one-piece Meehanite casting bed provides superior accuracy, durability and reliability. BNC-3500 is capable for heavy duty cutting. Large working capacity (turning diameter 890mm, turning length 1M~6M) turning length 1M~6M) with wide selection of spindle bores including the largest bore of 355mm for a wide application of various industries. Large bore is particularly for oil & gas industry products manufacturing.

MAIN FEATURES

- Fanuc OiTF Control with 10.4" LCD

- High rigidity and precision of manufacturing

- High efficiency output

- Hardened & ground bed ways

- Automatic lubrication system

- Extremely wide bed

- 254mm spindle bore

Milling Machine, ARGO Make- Taiwan

Very accurate and reliable in its kind of machines. Precise and superior quality machining capabilities.

| Spindle Motor | 5HP |

| Spindle Speeds(rpm) | 80-3800 |

| Spindle Taper | ISO 40 |

| Spindle Center to Column Face | 172mm – 756mm |

| Spindle Nose to Table Top | 0mm – 400mm |

| Quill Diameter | 100mm |

| Ram Travel | 458mm |

| Ram Swivel | 360deg |

| Working Surface | 305mm x 1270mm |

| Longitudinal Travel | 820mm |

| Cross Travel | 380mm |

Manual Lathe Machine: Denver Make, Taiwan

This machine is suitable for heavy cutting, easy operation, high tenacity, stability and heavy workload, which are good for heavy turning of mold, gear, wheel, shaft, central spindle etc.Designed for heavy duty cutting; this base is made of high quality Mechanite casting and design of rigid construction increase the loading capacity and processing stability.

Technical Specifications

| Swing over bed | 660 mm |

| Swing over cross slide | 400mm |

| Swing over gap | 930mm |

| Distance between centers | 3170mm |

| Spindle bore | 80mm |

| Spindle Speed | 23-1300 rpm / 12 steps |

| Width X Length of bed | 420mm X 4600 mm |

| Electric | 50Hz/3Ph |

Radial Drill Machine – Energy Make, India

Heavy duty and precise in operations.Double column construction for rigidity and effortless centering.Generously proportional & well adequately ribbed base plates, column and arm for maximum rigidity and minimum deflection.Arm guide surfaces are precision ground.Precision hardened and ground spindle.Special arm elevating safety device is provided to prevent arm from down

Technical Specifications

| Drilling Capacity | 50/60mm |

| Spindle Speed | 12 / 40 – 1700 |

| No of feed / range | 6 / 0.12 – 1.25 |

| Distance between centers | 3170mm |

| Drilling radius | 530 / 1500mm |

| Drill head traverse | 970mm |

| Spindle Travel | 325mm |

| Working Surface | 1490 x 910 |

Bandsaw Machine: Maxmen Metal Make, India

Features

- HYDRAULIC BLADE TENSIONING

- HYDRAULIC ARM LIFTING / FEEDING

- HYDRAULIC JOB CLAMPING/DECLAMPING

- POWER DRIVEN WIRE BRUSH

Technical Specifications

| Cutting capacity | 530 mm Round, 530 X 530 mm Square |

| Cutting speed | 20-100 Mt/Minute |

| Blade size | 6900 X 54 X 1.6 mm |

| Drive Motor | 10 HP, 1440 RPM |

| Hyd.Drive Motor | 2.00 HP, 1440 RPM |

| Drill head traverse | 970mm |

| Coolant Pump | 0.16 HP,2800 RPM |

| Hyd. Reservoir | 80 Ltr |

| Coolant Reservoir | 80 Ltr |

| Approx Nett Weight | 3500 Kg |

| Overall Dimensions L x W x H mtr | 3.3 X 1.5 X 2.3 |

| Cutting Taper Accuracy | + 0.1 mm |

| Cutting Length Accuracy | + 0.2 mm |

Mig Welding Machine: Exagon Make, Italy

Powered by inverter technology, the EXAGON 400 combines MMA, MIG-MAG & TIG in a single machine, offering exceptional welding performance. Featuring advanced electronics and a reinforced structure, this station guarantees maximum productivity, even in the most hostile environments. Powerful, sturdy and versatile, the EXAGON 400 takes welding to the next level

Best Suited for Oilfield, naval and railway construction and metal works:

Increased productivity due to strong duty cycle (400A @ 60%) & Optimized cooling because of the air-tight ventilation corridor that helps insulate the electronic components from the dust.

TIG Welding Machine: GYS Make, Italy

Designed for professionals, the TIG 300 DC is adapted for complex TIG and MMA welding operations. Intuitive, this welder allows to perform high quality welding operations on soft and stainless steel. Its proven technology provides excellent results to industries (Pipework, petrochemical, boiler work)

ARC Welding Machine: REXEL Make, Italy

Advantages

- Highly efficient and power saver

- Constant current characteristics irrespective of arc length variation

- Stepless current variation

- Excellent welding characteristics and performance

- Smooth and stable arc with minimum spatter

- Greater efficiency

- Site safety achieved with in built VRD

Application

- Ideally suitable for light and medium fabricators, shipyards, pressure vessel fabrication

- Multi-storeyed /heighted structural fabrication works